Mobile Robots

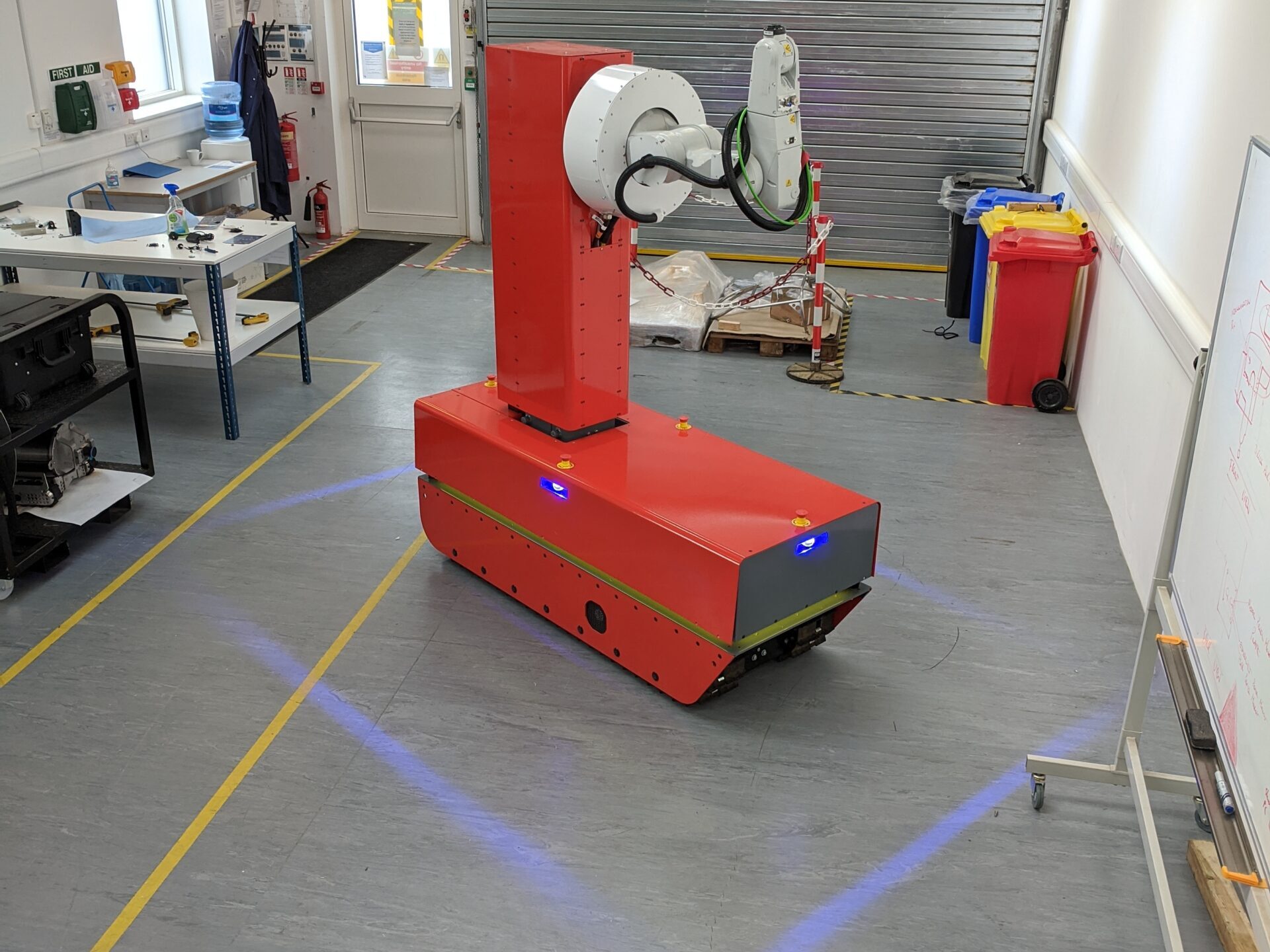

Autonomous Construction Site Robot

The aim of this project was to develop a construction robot that could perform key on-site activities, specifically drilling holes in the underside of concrete floor slabs to enable fixings for services and suspended ceilings. A mobile robot with a telescopic lifter and manipulator was developed to accomplish this task.

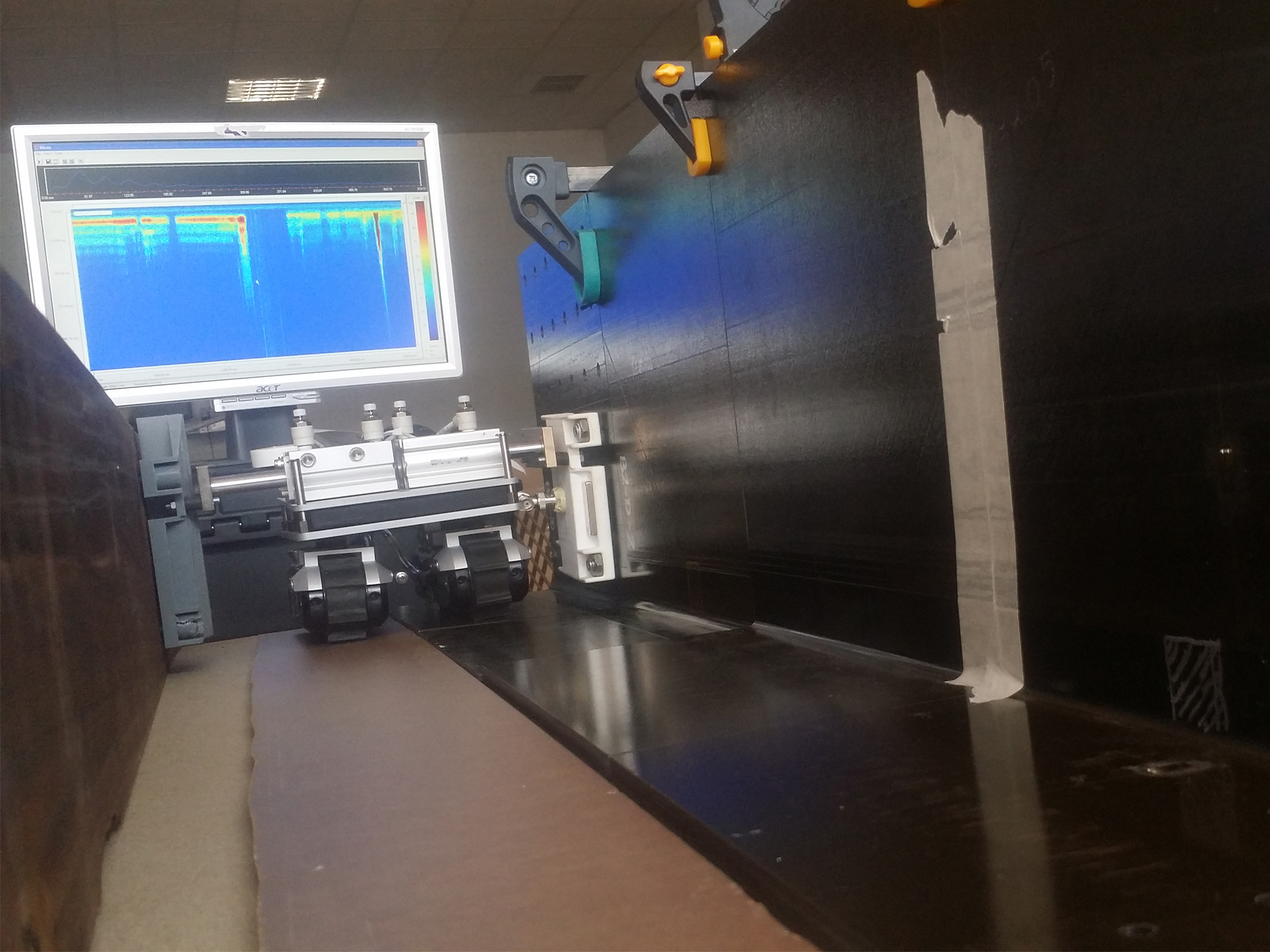

Magnetic Adhesion Inspection Crawler

This robot was built to climb a wall with a ferrous surface to perform inspections. The single-axis gantry mounted to the front of the robot was used to perform the scans using an attached sensor.

Aileron Internal Wall Inspection Crawler

This robot was developed to inspect and detect critical fatigue within the internal walls of an aircraft wing. The system uses two tracks for locomotion and pneumatics for the sensor actuation.

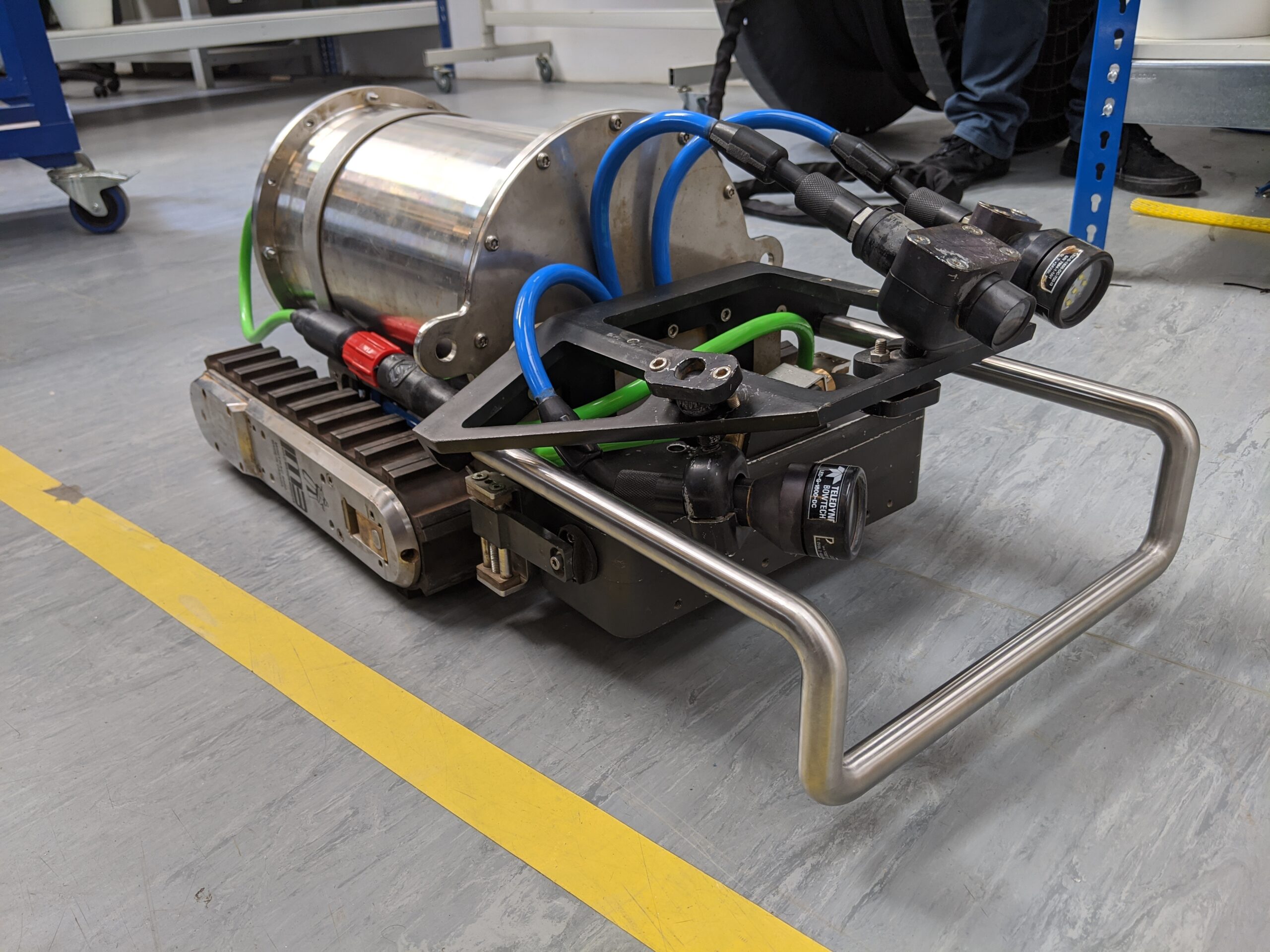

Fuel Tank Inspection Tracked Crawler

This robot was designed and built to perform inspections within water and fuel tanks. The phased array sensor on the front of the robot was used to detect corrosion within a tank.

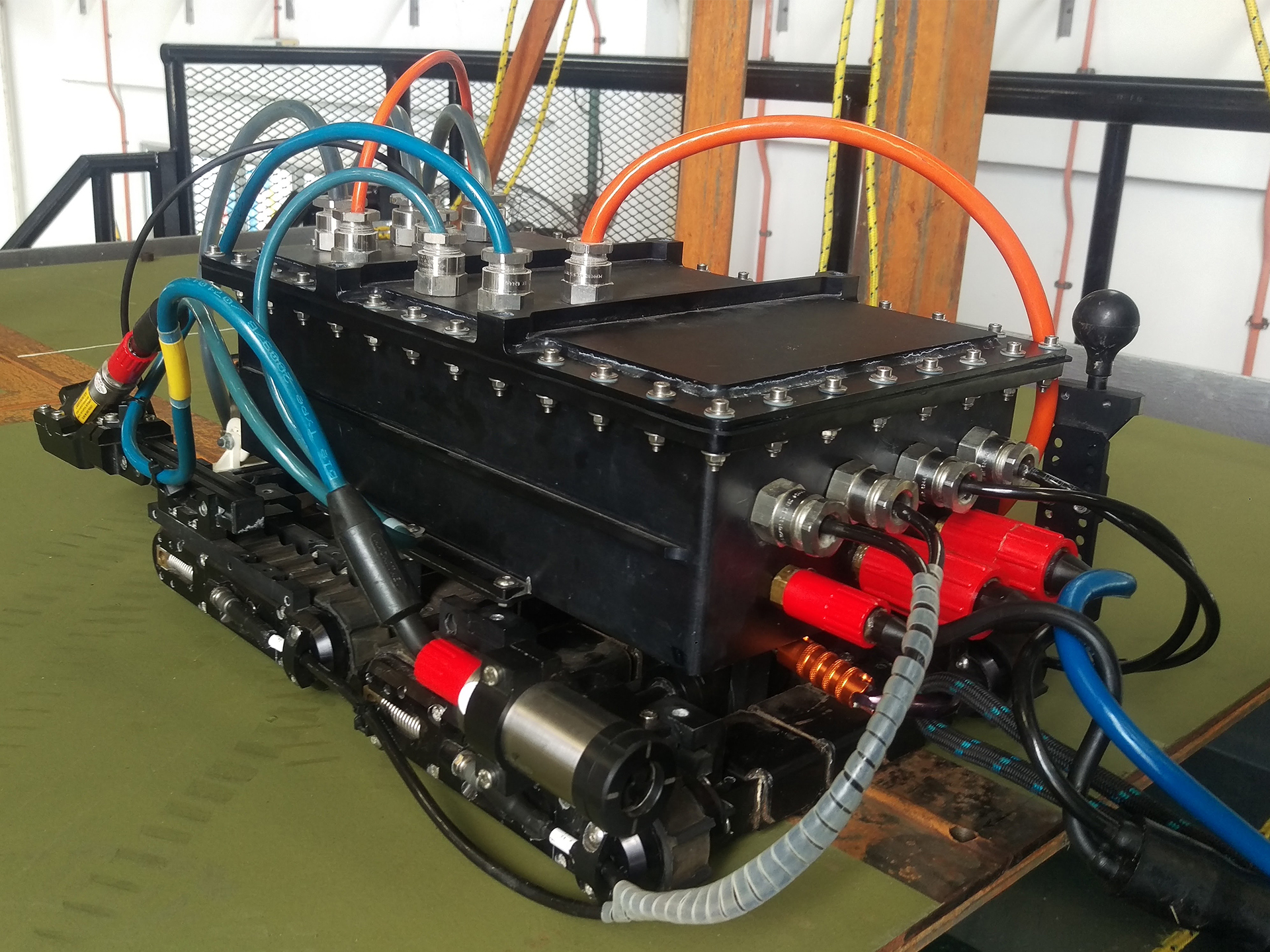

Ship Hull Inspection Crawler

This crawler was designed to perform underwater ship hull weld inspections. The system uses four tracks to provide locomotion and several sensors to provide feedback to the user. An umbilical cable connects the robot to the command station on the surface.

Vacuum Adhesion Crawler

This robot was developed to use vacuum adhesion to climb non-ferrous surfaces. To reduce weight on the platform, wireless Zigbee RF modules were used for robot control communications.

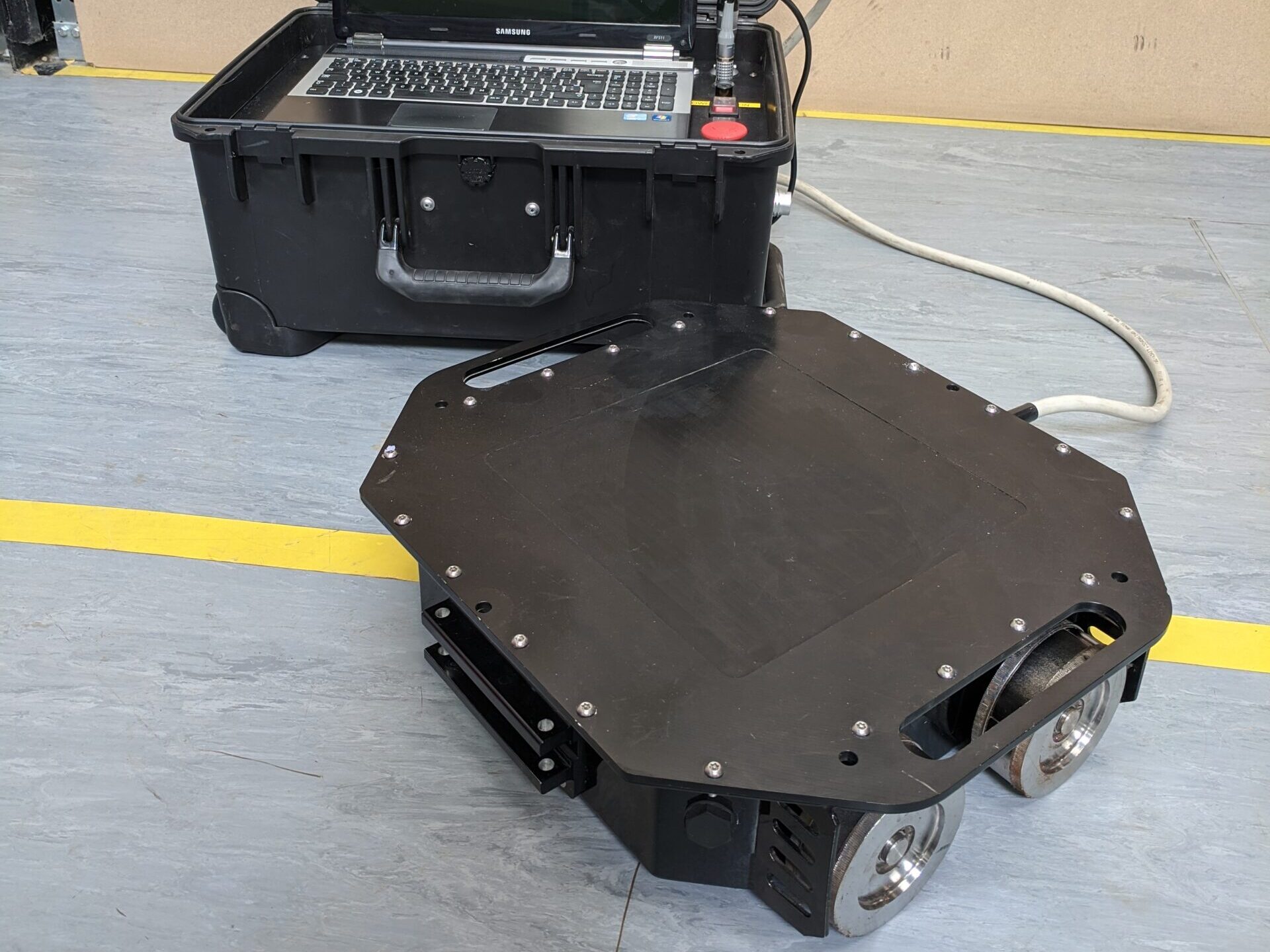

ATEX Certified Wheeled Crawler

We developed this robot a couple years ago to perform inspections of in-service fuel tanks. Due to the dangerous nature of this environment, we had to design the system to meet all relevant ATEX standards and regulations.

Magnetic Adhesion Crawler

This was another crawler designed to climb ferrous surfaces. The difference with this version is that it uses magnetic wheels as opposed to belly magnets.